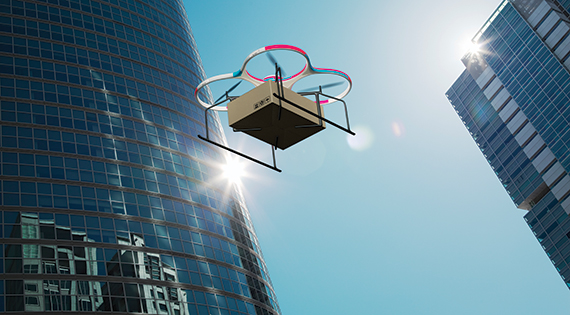

Drones generate scary tabloid headlines. Maybe they speak to deep-seated childhood fears of UFOs or gulls swooping out of the sky to plunder ice cream. Whatever, Amazon’s talk over the past few years about using unmanned aerial vehicles (UAVs) to deliver goods has excited press and public alike.

Drones generate scary tabloid headlines. Maybe they speak to deep-seated childhood fears of UFOs or gulls swooping out of the sky to plunder ice cream. Whatever, Amazon’s talk over the past few years about using unmanned aerial vehicles (UAVs) to deliver goods has excited press and public alike.

In July, the Civil Aviation Authority granted the online retail giant special permission to test drones without the usual rules that apply, such as pilots maintaining a “direct line of sight” to the drone and manning only one drone at a time. Amazon has been trialling drones at an R&D base in Cambridge.

If Amazon can get drone delivery to take flight, will the logistics market be affected? Most are reserving judgment, with the main reservations being the distance drones can travel, the weight they can carry, and exactly how deliveries will be completed.

But the journey has been started. Jon Sleeman, EMA head of industrial and logistics at JLL, says: “I think there’s less cynicism now than there had been. Without regulatory change, nothing is possible, but the government’s readiness to look at it is a significant step.”

Some are less diplomatic. Toby Pocock, founder of drone business Skyvantage, says: “I think the idea of mass-market drone delivery is laughable – there are safety issues, the cost issues mean you’d have to be close to delivery depots, and there’s the landing issue. There are so many questions.”

As things stand, the prevailing view is that the range of delivery drones will be restricted to just 10 to 12 miles, while their payload will be just 5lbs – fine for books and CDs, not so for groceries.

Sleeman says: “Everything’s still open to debate, but if deliveries were restricted to 10 miles, you’d have to put in place a significant number of warehouses and launch points.”

The current trend, for Amazon and other large retailers, is for huge national and regional supersheds, whereas in a drone-served world, any large conurbation would require several smaller warehouses dotted around its outskirts. That is workable – there are empty DIY stores and big-box units around most cities. But it would all cost.

Sleeman says: “If more warehouses were needed, it could be an opportunity for the industrial market. It could bring into demand any suitable sites with a well-populated catchment area.”

Len Rosso, head of industrial and logistics at Colliers International, is optimistic. He says: “I don’t think drones are all that far off. Obviously, there are issues to overcome, such as where you can fly them. But you can definitely see the efficiencies that could be driven.”

The sticking point, he thinks, could come with collection and delivery. “Is it going to be click and collect, with facilities around neighbourhoods? If so, is that such a big benefit, and if not, why do it? The technology is all there, but the task is to make it work practically.”

The question of “why?” is the key.

Sleeman says: “We know that a van can do multiple drops in a day – potentially a hundred in an eight-hour shift. What’s the most that a drone could do in the same time? At the moment, it’s probably more economical by van.” The road network, for now at least, is still good enough.

That said, Amazon’s fastest delivery is billed as Prime – one that customers will pay a premium for. A big struggle for logistics right now is meeting demand for one-hour delivery. If greater certainty could be given to delivery times, the public might be receptive.

And professionals see a use for drone delivery. Pocock says: “There’s definitely a case to look at regarding remote rural areas or islands, to transfer medical supplies and other essentials.”

And drones are used in other areas of property. According to Interserve, a roof survey carried out by UAV takes 20 minutes and costs £900, opposed to weeks and £16,000 for scaffold access.

The drone drama is yet to influence real estate decisions. Rosso says: “Is it something occupiers ask about at the moment? No. But major occupiers are constantly exploring their options. When this looks viable, that might change.”

What Amazon has to say about drone delivery

An Amazon spokesman says: “With Amazon Prime Air, we’re developing a rapid delivery system that is safe, environmentally sound and enhances the services we already provide to millions of customers.

“Today we are testing a range of vehicle capabilities, including redundancy and sense-and-avoid technology. We are also testing many different vehicle configurations, working to determine what vehicles are best suited for what environments. Testing is going well, and we are very pleased with the R&D progress it has enabled.

“Some of our vehicles will have a range of 10 miles or more. They will also carry packages weighing up to five pounds. It turns out that the vast majority of the things we sell at Amazon weigh less than five pounds. We are excited about our new agreement with the UK government and are keen to work closely to make drone delivery a reality for customers safely and soon.”

Other disruptors

Other disruptors

Big tin sheds with packers and pickers, trucks rolling in and out. That’s logistics, right? No, says Ed Greig, disruptor at Deloitte Digital. “There’s huge change right across logistics. Warehouses are becoming smarter. Connectivity is the key. At a large business, it’s vital that the property team works closely with the tech team because real estate needs to be flexible enough to accommodate change,” he says.

Developers such as P3 Logistics Parks are already installing electric charging points not just for cars but for lorries. And the likes of Amazon are already using elements of robotics, enabling them to build taller and work faster. Ian Worboys, P3 chief executive, says: “The growth of robotics in warehousing, along with driverless lorries, will be with us much more quickly than people think.”

Martin Summerscales, retail consultancy leader at CBRE, points out that order fulfilment has been a tough cost for e-commerce retailers to battle.

“Delivery costs, handling returns, missed deliveries. The ‘serial returners’ are a huge issue. I think over 10 years we’ll see the cost of fulfilment come down hugely. Picking and packing is still done in a very antiquated way.”

One US remotely managed robot model presently costs $4 (£3) an hour, which is expected to come down to $1.50. That’s 10 times cheaper than the US living wage – and robots don’t get sick or go on holiday.

Food for thought. As are driverless vehicles – supermarket delivery vans and trucks as much as cars. Uber, which in August launched autonomous vehicles (“human-supervised,” for now) in Pittsburgh with Volvo, has this year acquired Otto, a driverless truck start-up established by engineers from Google’s self-drive programme. Google will not, it’s fair to say, be allowing Uber to have it its own way.